Solution

OptiPlan Software for Large Manufacturers

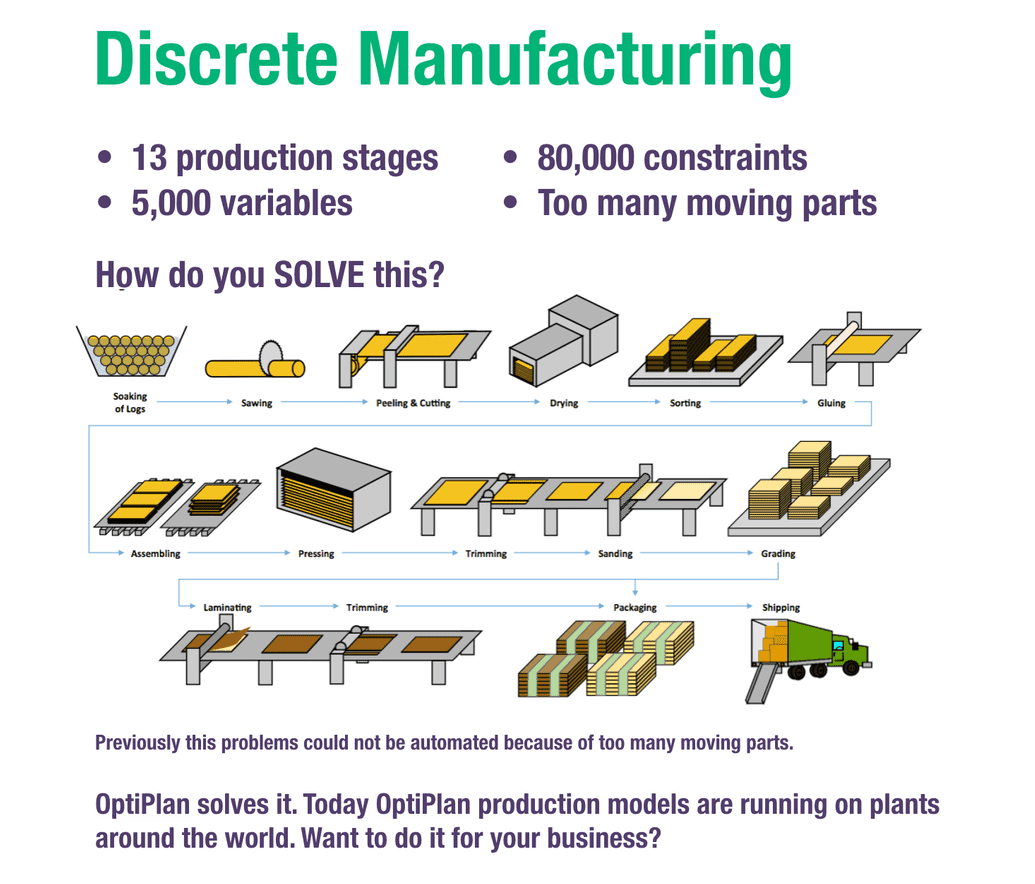

Here is why we can schedule production and equipment so much better than anyone else:

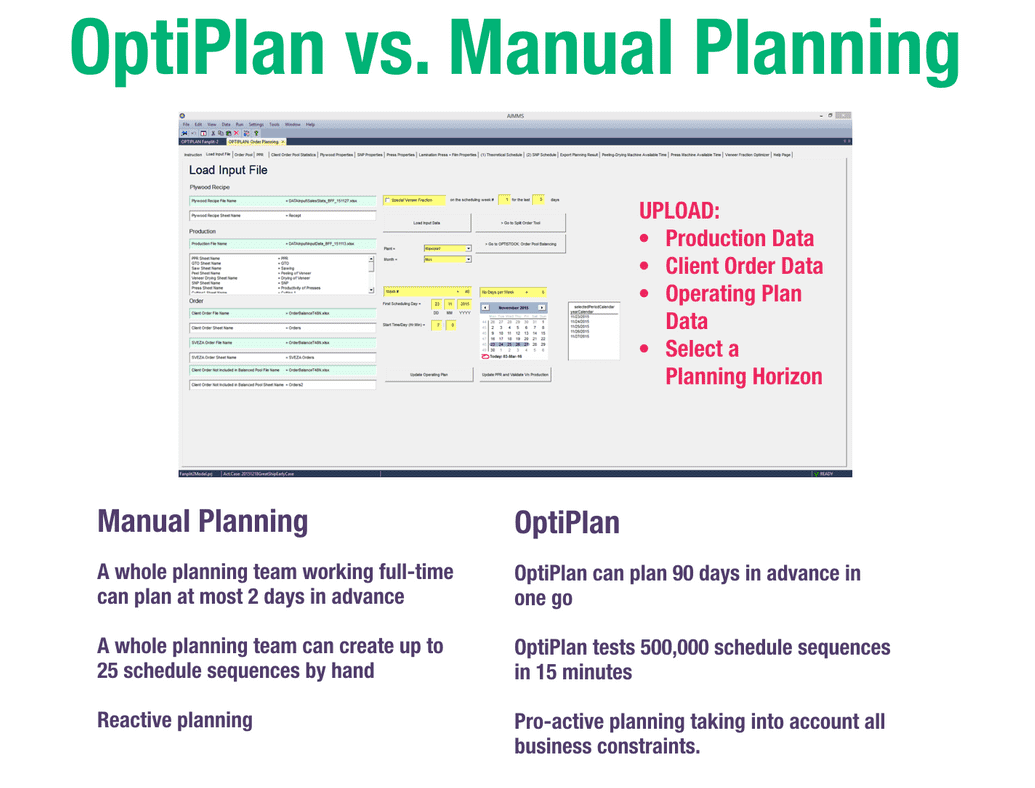

Currently scheduling is often done by a team of human planners with tens to hundreds Excel sheet and data base exports from an ERP system. OptiPlan takes this to a new level and uses advanced math and NASA-grade optimizers to make these schedules faster.

- Instead of 25 sequencing variations by a team, OptiPlan can check over 500,000 different schedules in under 5 minutes.

- For plywood production, OptiPlan creates an optimal plan for a pool of 150 orders with 320 SKU positions in two minutes (checking 500,000 schedules for a problem with 8500 variables and 5000 constraints).

- For plywood production again, for individual bottleneck stages, OptiPlan checks 90,000+ combinations of schedules under 5 minutes, each with 140,000 variables and 20,000 - 50,000 constraints.

People tried to solve this problem manually before!

Features and Benefits of the OptiPlan family

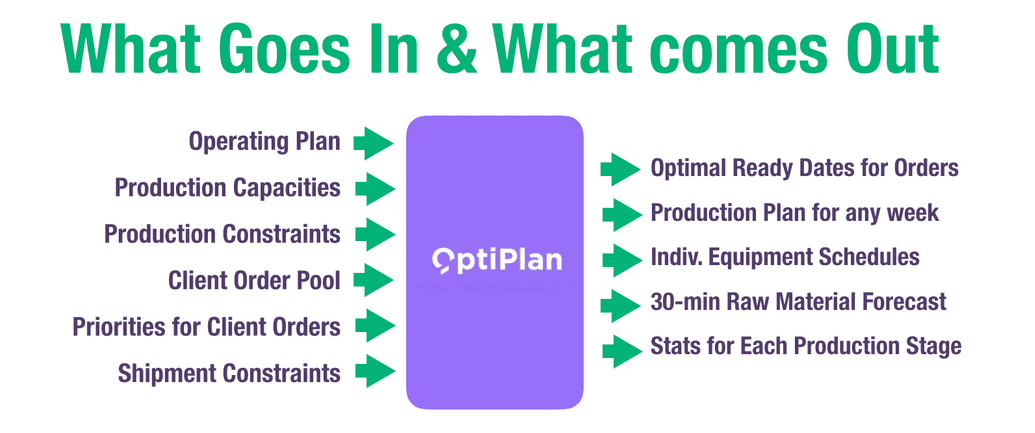

Here are some interesting features and benefits that OptiPlan can provide that no other software can:

- Optimal long term production schedules w.r.t. business targets, raw material usage, equipment

- Increased output with existing equipment & raw materials

- Work in process cost is cut by up to 80%

- Flexible objectives (maximize volume vs. maximize finished orders vs. minimize WP cost)

- All production constraints satisfied (up to 100,000 constraints)

- Explicit Optimization of a Business Plan for profitability is enabled (Creation of an optimal product portfolio)

- In the absence of actual client orders for the longer term planning, OptiSell creates robust sales predictions for portfolios of popular and well-sold products (per SKU). These have a guarantee to be sold within the prediction horizon.

- Frozen capital & overproduction is avoided by design thanks to OptiStock. In the absence of client orders during less active seasons, OptiStock plans orders for production which maximize profitability, and raw material usage, while keeping inventory under control.

Minute-by-minute schedules are easily created for each piece of equipment in the production process

OptiPlan takes the entire manufacturing process into account and makes sure no equipment is sitting idle.

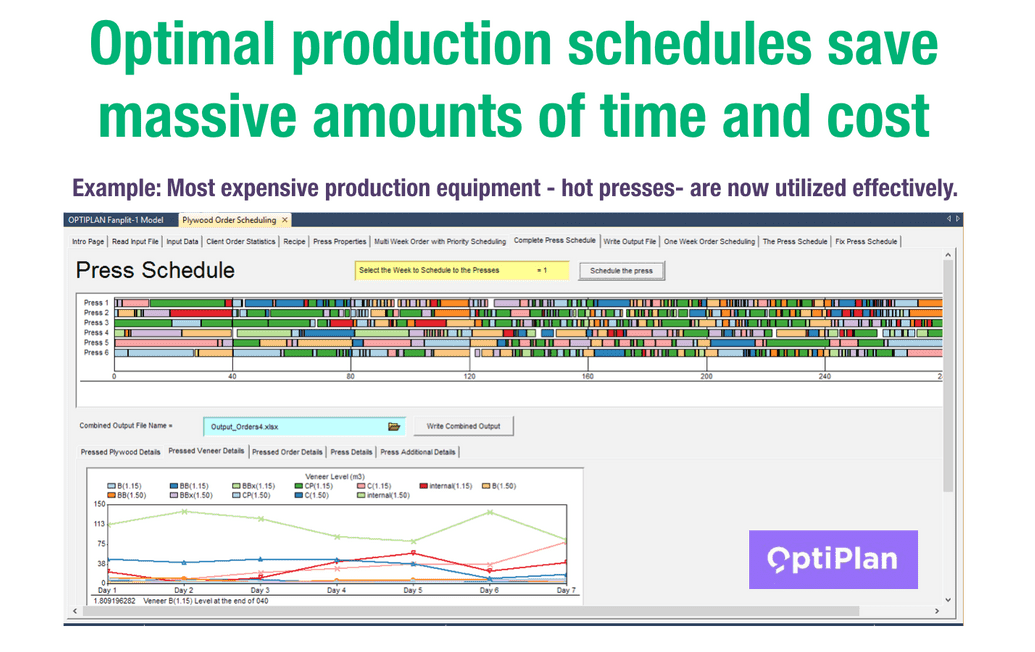

Example for plywood production:

With this optimized schedule for hot presses, the presses are never left idle, always working, and always have packages to process.

To achieve this, OptiPlan checks 90,000+ combinations of schedules under 5 minutes, each with 140,000 variables and 20,000 - 50,000 constraints.

NASA-grade optimizers make sure we solve this problem in under five minutes.

Our client confirms that their total work in process costs on the first plant are reduced by 3-4x (a minimum of 75%!).

Clients are happy about the long-term predictability and faster production cycles

Example for plywood production:

Previous manual approach to production scheduling was resulting in client orders completed in 10-17 days on average. Now the the orders are completed in 1.7 days on average. This is 5x to 10x faster.

You can imagine that clients are quite happy, because there is a lot more predictability for them. Clients can order trucks and wagons on specific dates and know their stuff will be ready. They don't need to commit to orders one to two months ahead. They are happy to pay 1-2% extra for this predictability!

What can the company do with this software:

| BEFORE | AFTER OptiPlan |

|---|---|

| Average completion time of an order was 10 days | Average completion time of a client order is 1.7 days |

| One planning cycle took all time of four planning specialists | One planning cycle with different scenarios takes a maximum of 4 hours to one specialist per week |

| Some grades of intermediate raw material were in excess, some in continuous shortage | All grades of intermediate raw material are now kept within optimal bounds to avoid idling and reach optimal usage |

| Clients always complained that they need to commit to buy products up to two months ahead. | Clients are happy to pay 1-2% more on each item because orders get delivered within two weeks exactly on a date announced on the week of making order |

| During seasons with little demand, warehouses were bursting with products made to not waste raw material, with capital frozen in the inventory for years. | Frozen capital is now avoided by design, because OptiSell informs planning which products to make to guarantee sales and take into account current stock levels. |

How we can help you:

So if you are a manufacturing, planning, or logistics leader, don't worry that the tools you currently have cannot do this type of advanced planning.

- We can adjust OptiPlan software family to your problem.

- We can provide you individual components to hit your goals.

- We can integrate OptiPlan software with your ERP system.

- We can streamline your supply chain and truly deploy lean methodology with 10x less money, and 6x less time.

- The best supply chain optimization software for lean manufacturing & logistics

- For large manufacturers that produce physical goods

- Deployed successfuly for several clients for daily and weekly operations planning (minute-by-minute)

- Multiple optimization targets: profitability, business plan, satisfied customers, warehouse and logistics targets

- Simple interfaces for planners, operators, and managers

- NASA-grade optimizers

- Connects directly to your ERP